5 Tips for Performing End-of-Year Inventory

As the year winds down, your fleet operation might need to schedule a final end-of-year inventory of your parts room. To successfully perform the task, follow these tips to ensure it goes smoothly and efficiently.

Plan Ahead

The end of the year can be a hectic time with staff members on vacation and vehicles trying to be serviced before the new year. Because of this, it’s important to plan and schedule year-end inventory as soon as possible. This can ensure you are properly staffed for the task.

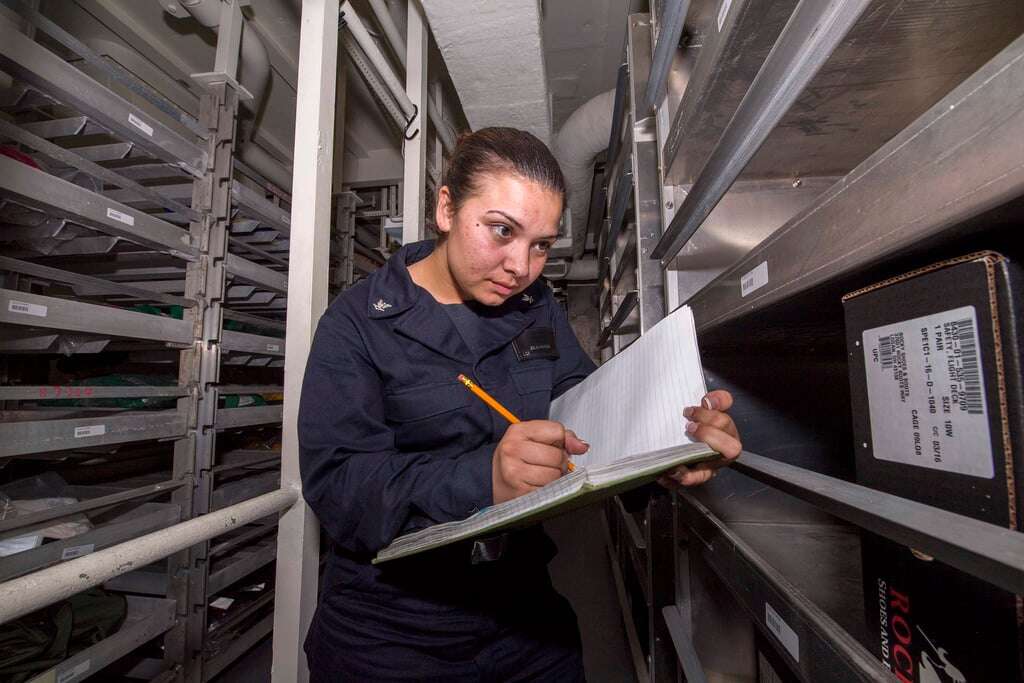

Get Organized

The more organized your parts room is before you start taking inventory, the easier the process will be. Labeling shelves, rows and bins will help identify where each part is located. Grouping all parts together and putting them in their assigned places on the shelves will make taking inventory much more efficient.

Get the Right Tools

Using barcoding tools can greatly reduce the amount of time it takes to perform inventory. If each part is labeled with a barcode, employees taking inventory simply need to scan in the part and tally how many of each one is present. If the barcode tools are connected to your operation’s fleet management software system, the inventory can be quickly accessed and reviewed, allowing your staff to spot errors so mistakes can be corrected during inventory.

Read How Island Transit Improved its Inventory Process with Barcoding Tools

Staff Appropriately

Performing inventory can go a lot faster if there are a couple of employees dedicated to the task. This way they can create a system for how to perform the inventory and can work together to get it done quickly. If you have a dedicated parts room staff, ideally have them take inventory since they know best where the parts are located and how they are organized.

Select the Right Time

When scheduling inventory, make sure you select a date and time that is convenient for your staff and the operation. You want to try to avoid a busy day in case the parts room is unavailable for a period of time, and so you’re not leaving the operation short-handed. You also want to select a day where you are fully staffed, and there isn’t an operation-wide meeting or other event.

To learn how RTA Fleet Management Software can improve your fleet operation’s inventory process, contact us today to schedule a demo!